The microwave oven transformer is possibly one of the simplest methods of making some big high voltage arcs, mainly because they are robust, cheap, and easy to hook up.

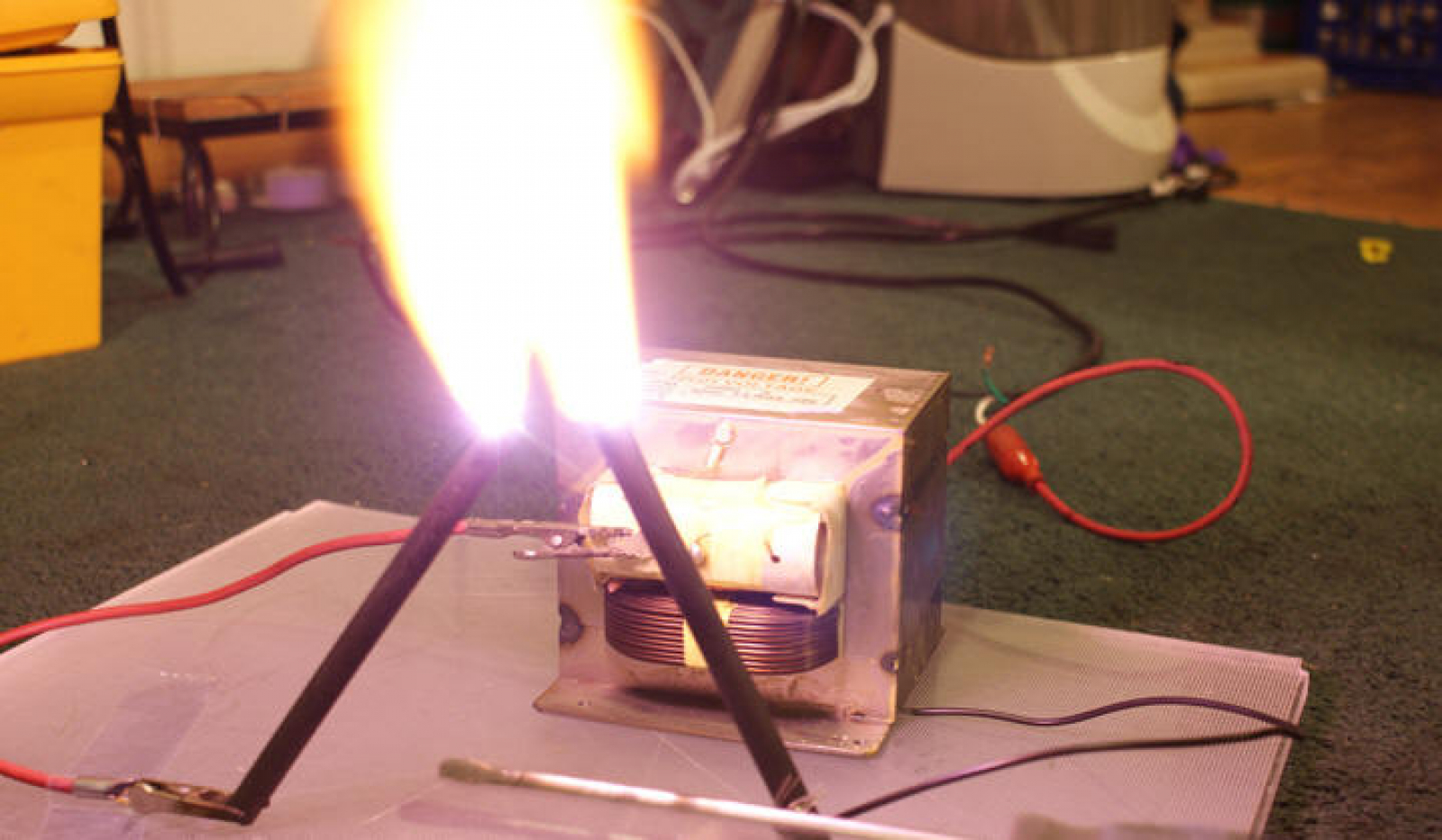

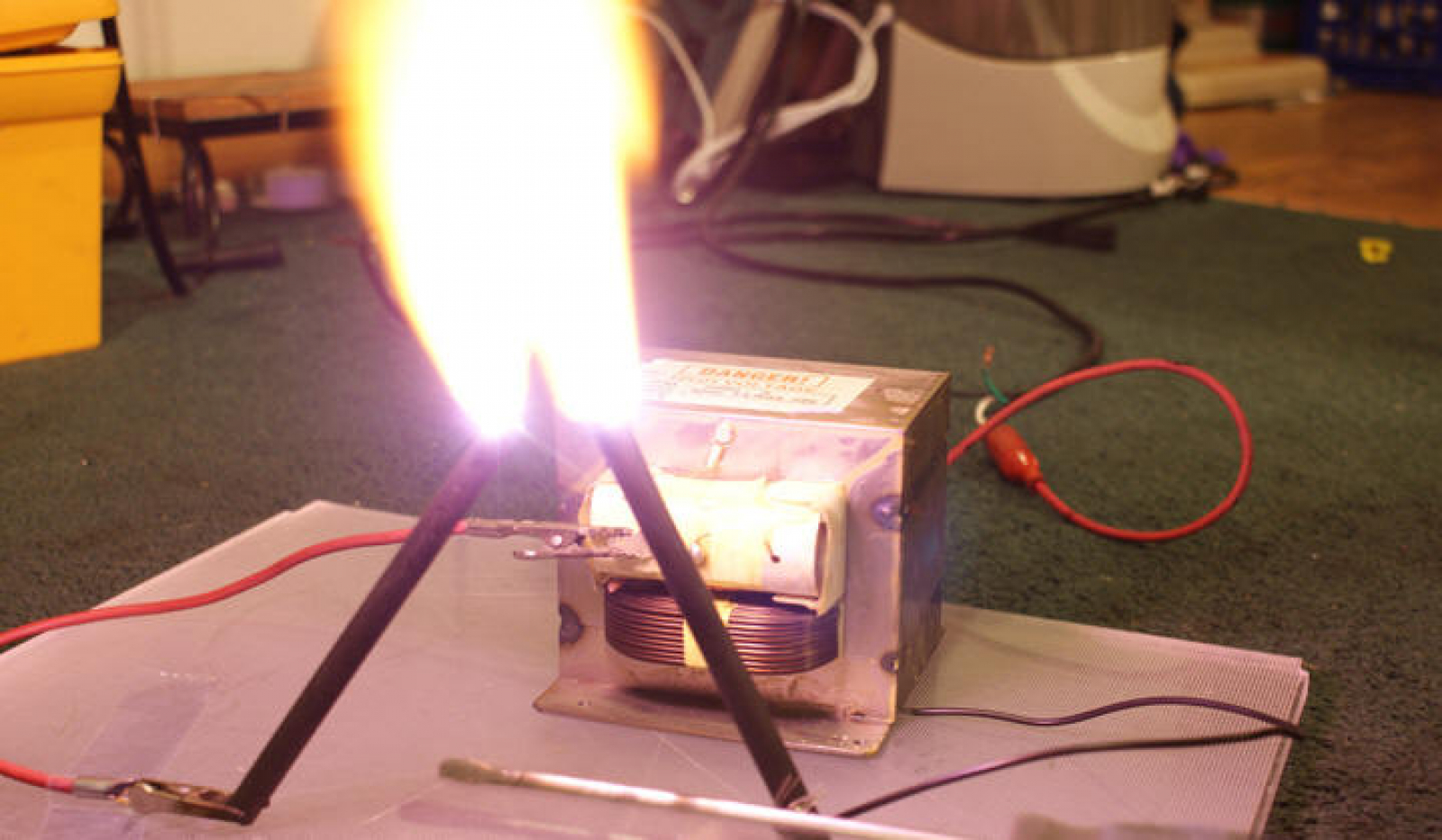

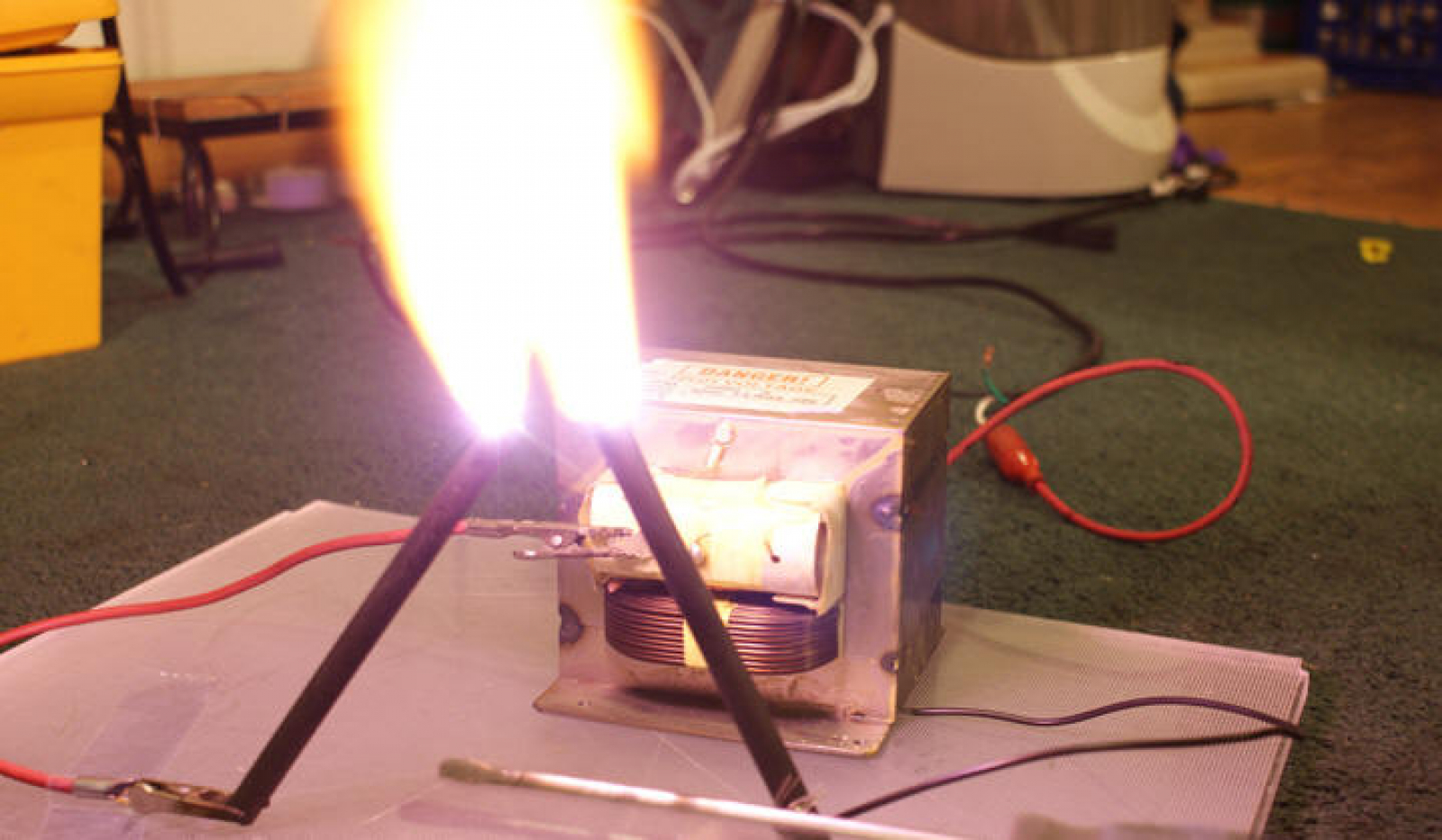

Here I have a picture of an

#MOT. The mains input is two blade connectors on the primary coil (thick wire). All you need to do is give power to those connections via a lamp cable or some other means and you've got 2,200V coming out of the thing. But where does the 2,200V come out?

Well, the HV output is a single blade connector on the secondary coil. It usually puts out around 2,200V at 1 amp (2,200 watts); certainly more than enough to kill you, so... DO NOT make contact with the high voltage! Seriously, DO NOT.

However, just because something can be deadly doesn't mean that it must be. Just don't touch the HV output and you'll live to tell stories about the MOT and its wonderful arcs (which are insanely bright by the way).

The ground connection on an MOT is the transformer's core. It is neutral so you can safely attach the MOT to a piece of metal and not worry about electrocution if you happen to touch it.

MOTs are a mass produced item and these days quantity is more important than quality. Because of this, they are designed with as little iron as possible and drawing an arc often saturates the core. Once a transformer is saturated it starts to draw a lot of extra amps; amps that do not make it to the secondary coil, but instead are wasted as heat. To prevent excessive current draw, MOTs are usually ballasted, and this can be accomplished a couple different ways.

By far the simplest method is just to use a long extension cord. Anything greater than 50 or so feet should limit the current enough that the MOT doesn't trip your circuit breaker. If you don't have a cord like this don't fret: there are more options.

An alternate ballasting option is to use another MOT an a series inductor. All you need to do is put the primaries of 2 MOTs in series, then short out the secondary of one MOT (see img). The one with the shorted secondary becomes a high current inductor, perfect for ballasting another MOT. This is the preferred method of current limiting since there isn't much that can go wrong and not too much power is lost as heat. It certainly adds a lot of weight though...

A third method of ballasting MOTs is to use a resistive ballast. Halogen lamps (the big 500W work lamp kind) make pretty good resistive ballasts. All you need to do is put one in series with the transformer's primary to limit its ability to draw current. Make sure you find a non-combustible way to mount them since those things get hot! Also, since they are glass don't touch them you as your finger oils will burn when the lamp is powered up and the resulting carbon will get hot enough to shatter the bulb.

Since MOTs are nothing but copper and iron they can be modified a couple different ways. One such modification is to knock out the magnetic shunts. The magnetic shunts marked in this picture increase the leakage inductance of the transformer, and this limits the current somewhat. If you want more current out of the HV side for some reason you can knock out these shunts using a hammer and a chisel. It takes a bit of doing but it's certainly possible, and once the shunts are knocked out you should be able to get more current out of the secondary, and thus longer, hotter arcs.

Here I have a video of an unballasted MOT. Look how bright that arc is! You better use some freaking sunglasses if you play with one of these. Arc eye is not fun.