XRay Transformers

Before small #cockroft-walton multipliers became inexpensive x-ray machines used to use large iron transformers. These things are the highest voltage transformers you'll likely ever come across, turning 120V (or 240V in euroland) into 50,000V, 75,000V, 100,000V or even 320,000V. Needless to say these are awesome.

Take these heads apart outside because they're filled with insulating oil. More recent tube-heads are filled with mineral oil, but some of the pre-1970s ones are filled with PCB oil, so take care to not dispose of it recklessly as it is a persistent environmental pollutant.

Take these heads apart outside because they're filled with insulating oil. More recent tube-heads are filled with mineral oil, but some of the pre-1970s ones are filled with PCB oil, so take care to not dispose of it recklessly as it is a persistent environmental pollutant.

Safety

XRTs pose some rather 'unusual' hazards for lack of a better term. Although an one might be rated at 70kV, this is actually it's voltage under a 5-7mA load. When unloaded that XRT is capable of producing up to 200kV, and that kind of electricity will gladly jump 8 inches through the air to bite you. This means a long, fiberglass insulator handle is absolutely required when you draw arcs from an XRT. A good rule of thumb is for every 100kV make the insulator 50cm long.Where can I get one?

Unlike things such as #neon-sign and the #microwave-oven-transformer, an XRT is not simply "plug and play". This is because you can't just buy an x-ray transformer all by its lonesome. Instead you must buy part of an x-ray machine and pull it out of there!.X-ray transformers are located inside the "heads" of the x-ray machines; the part that the dentist puts next to your face when you get your picture taken. These heads typically sell for about $150 used, and they contain both the x-ray transformer and a nice x-ray tube. You could then sell the tube for about $60, or keep it for later experiments.

How do I connect one?

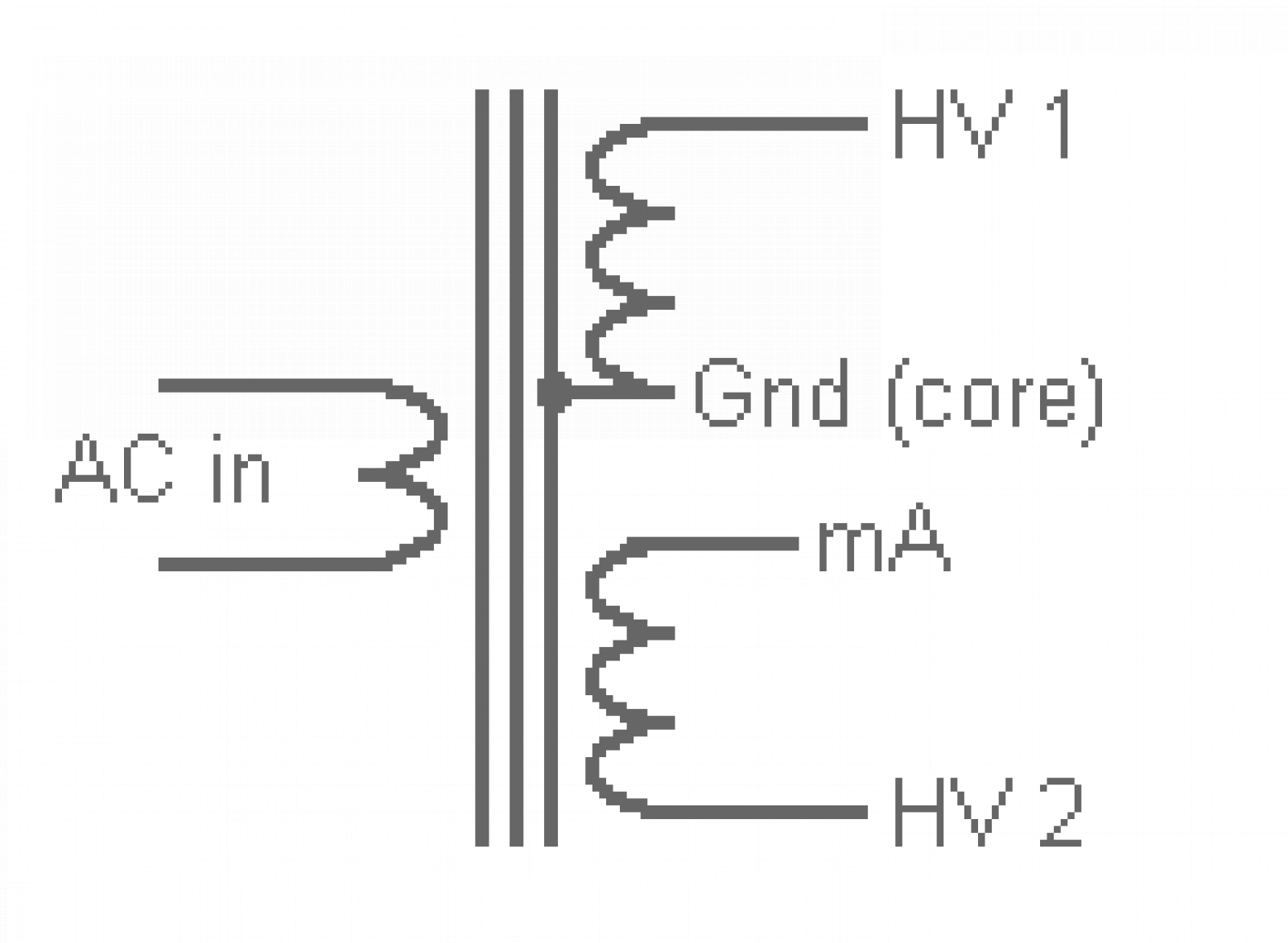

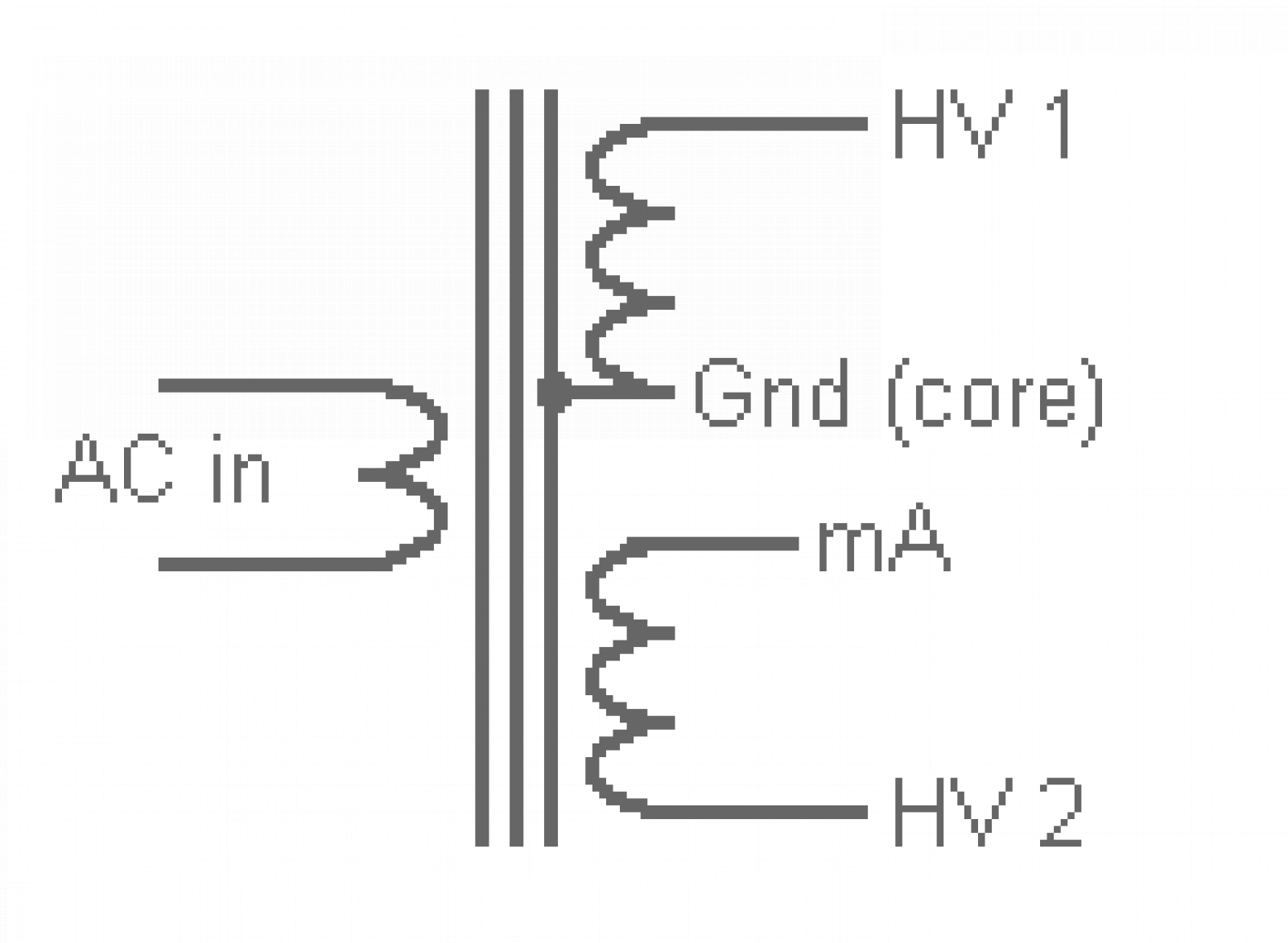

A typical XRT has 6 connections. The thickest of these connections will be the primary coil and these two wires get connected to the mains. Since an XRT is a center tapped transformer there will be two HV outputs, and these are usually just balls of solder on the windings. The ground of one HV secondary will be connected to the core, while the ground of the other secondary will be connected to a "mA" terminal on the x-ray head. To measure secondary current you may put a mA meter in between this wire and the core. If no measurement is needed you may solder the wire to the core.

How do I run one?

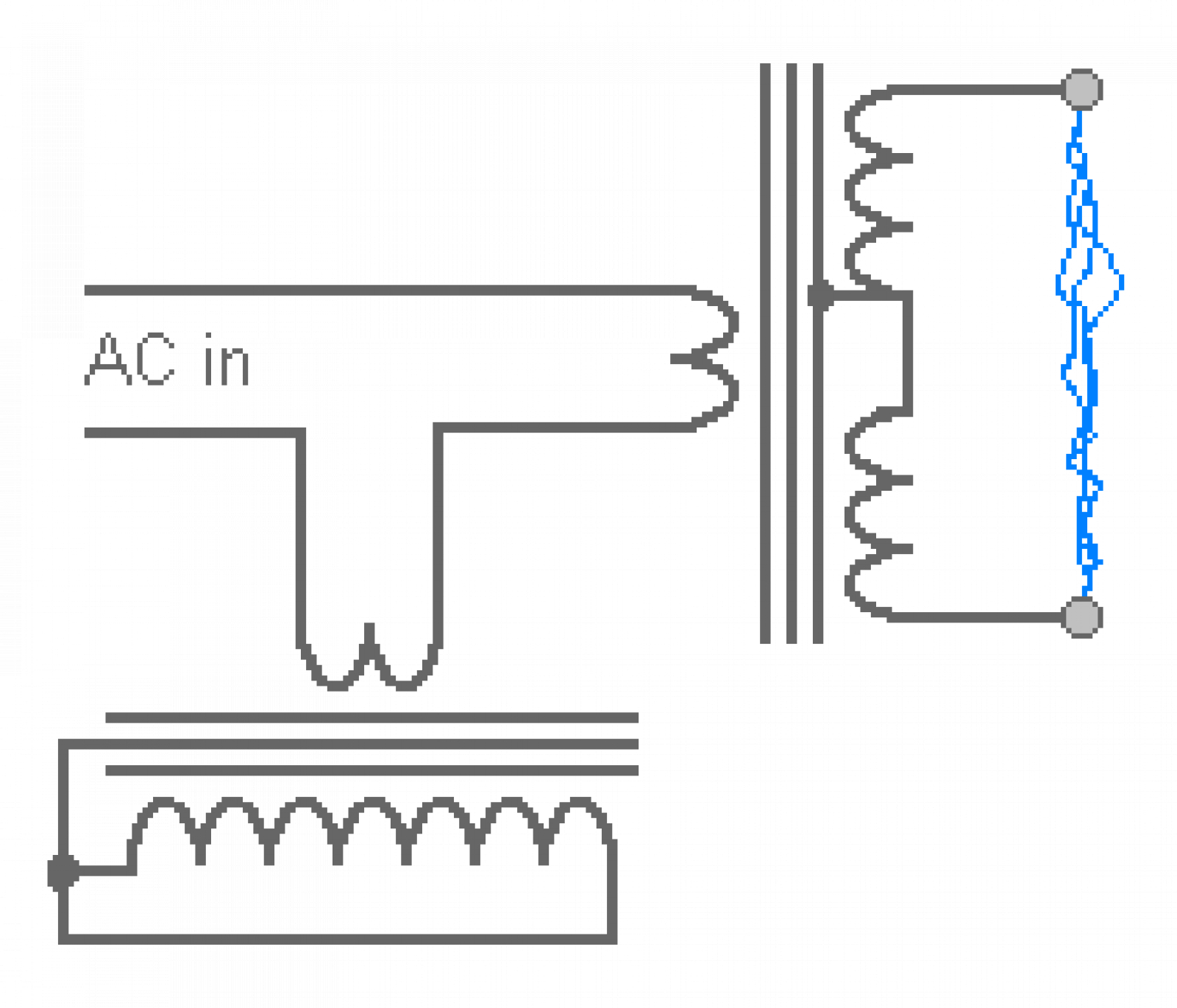

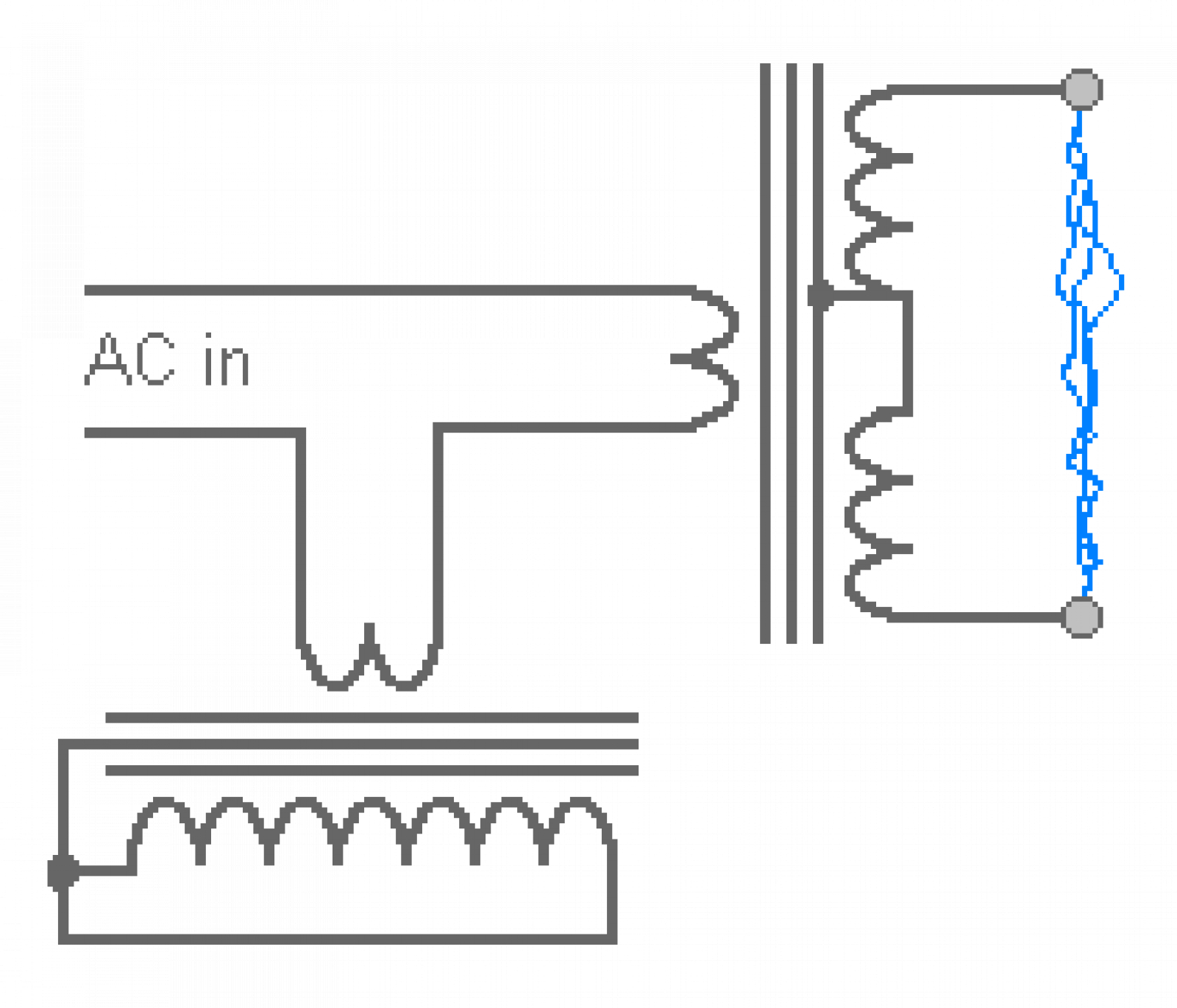

X-ray transformers are not designed to be run in open air, and if you attempt that the xrt will die immediately from unwanted arcing. To prevent the destruction of your precious transformer you'll need to put it under oil. Any oil will do, including mineral, vegetable, peanut or canola oil. If you decide to use an organic oil be warned that you'll have to replace it every five months or it will go rancid and stink up your transformer.The purpose of the oil is to provide better insulation for the transformer to prevent unwanted arcs. If the transformer has been out of oil for more than 20 minutes chances are air bubbles have formed between the windings; air bubbles that will cause insulation issues. Ideally one would pull a low vacuum on the transformer to get all the air out of the windings, but in the case that you don't have a vacuum pump or refrigerator compressor there is an alternative, yet messier option. That option is putting your hands in the oil and massaging all the air out of the windings until you can squeeze out no more bubbles. It's not as good as pulling a vacuum but 9 times out of 10 it will work.Ballasting

X-ray transformers are not current limited; if you try to plug an XRT into the mains it'd be a near short circuit and draw currents in excess of 60A. Needless to say this is bad. Due to the high powers involved with an XRT a resistive ballast won't be a good idea because the resistor would get insanely hot. An inductor is a much better option for ballasting XRTs, and the perfect inductor for the task is a shorted MOT. Simply put the MOT's primary in series with the XRT's primary and then short out the MOT's secondary. Viola, you now have a reliable ballast that doesn't get hot and costs next to nothing.